With a wide range of functions and applications,

The infinite possibilities of Brushtech and brushes!

R&D technology

R&D technology

Brush production and characteristics

Process of making a brush

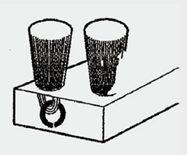

1. Implanting Type- Pin Fixing Type (Staple Type)

It is a method in which bristles are fixed to the hole-processed material by U-shaped stapler.

The D-shaped staple is a method of bending a cut wire in a D-shape through dedicated equipment and then planting it to the bottom of the hole.

This structure can be found in most brushes as the most common and effective way of making brushes.

In addition, this implanting method is most often used as a structure that can maximize the resilience and elasticity of the bristles.

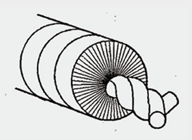

2. Tube Type (Twist-in-wire)

It is a structure that inserts a bristle between two or more wires and twists it to fix the material.

It is usually called tube brush, bottle brush, and pipe brush, and is mainly used for deburring (cleaning inside pipes) after hole processing of applying metal material.

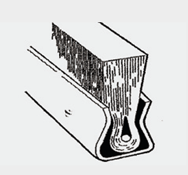

3. “Metal Strip Type"

Bend the thin plate from the coil into a U shape in a molding machine, then place the bristles on the channel and press the core wire to press the bristles to fix the channel and the bristles.

The channel type is the most durable brush work method, and the brush bristles are uniform and durable, so it is often used for industrial purposes.

It is commonly used to clean and finish printed circuit boards or metal planes such as aluminum and steel coils.

In addition, a long brush is made this way to prevent hemlines or shoelaces from getting stuck on either side of the escalator.

4. Adhesive Type (Epoxy type)

As new technologies gradually developed, fixed methods using epoxy were introduced.

This method is mainly applied to disk brushes.

This method is more suitable for long-term use with strong force because the brush bristles are closer than any other work method, so they do not collapse easily and have good resilience.

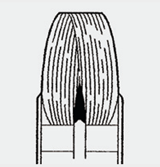

5. Wire Drawn Type

It is the oldest and most traditional method of securing the penetrated holes of the product using continuous straps.

It has a needle-like shape on the back, is simple to make and requires no equipment.

It is usually used for manual use, but can also be used for flat floor cleaning equipment and others.

브러쉬모 특성

| 6-Nylon | 66-Nylon | 612-Nylon | Polypropylene | Polyethylene(PET) | PBT | PVC | |

|---|---|---|---|---|---|---|---|

| Density(g/㎤) | 1.13 | 1.14 | 1.08 | 0.9 | 1.37 | 1.31 | 1.35 |

| Melting Point (℃) | 225 | 255 | 215 | 165 | 250 | 225 | 95 |

| Water Absorption(%) | 9 | 9 | 3 | <0.2 | <0.5 | <0.5 | <0.2 |

| Maximum Working Temperat | 80 | 100 | 85 | 70 | 115 | 100 | 55 |

| Bend Recovery(%) | 90 | 90 | 95 | 55 | 60 | 80 | 50 |

| Alkali resistance pH > 7 | good | good | average | average | poor | average | poor |

| Acidity pH < 7 |

poor | poor | poor | good | poor | average | good |